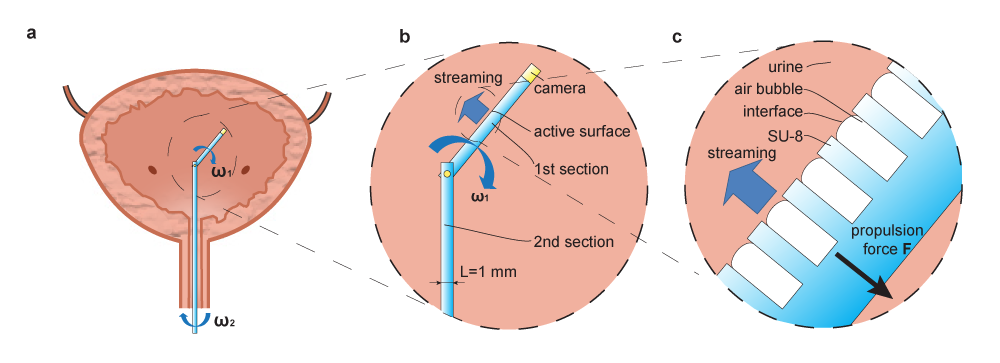

Figure 2.1: Schematic of the miniaturized endoscope driven wirelessly by ultrasound. A surface is microfabricated (c) such that it supports an array of micro-bubbles. The oscillation of the air-liquid interface at the bubble surface causes liquid streaming and thus generates a propulsion force (due to the recoil) on the device (b). The robot arm can now be powered and moved wirelessly to position a camera (a). The robot arm is only 1mm in diameter and thus much smaller than current endoscopes.

Introduction and problem: Endoscopy enables minimally invasive procedures in many medical fields, such as urology. However, current endoscopes are normally cable-driven, which limits their dexterity and makes them hard to miniaturize. Indeed, current urological endoscopes have an outer diameter of about 3 mm and still only possess one bending degree of freedom. In order to avoid anesthesia and to enable routine inspections, it would be advantageous to develop an endoscopic camera arm that needs no cables or wires. Is it possible to actuate an endoscope that is smaller than existing endoscopes? This calls for a new kind of actuator – one that has a simple structure and is powered wirelessly such that it can be miniaturized and integrated more efficiently.

Ultrasound has been widely used in medicine and it has also been proposed as a means to transfer power wirelessly. However, common approaches first convert mechanical vibrations to electrical power using the piezoelectric effect, and then in a second step utilize the electricity to power a device. This conversion process adds additional complexity and suffers from low efficiency. In this project, we have developed a wireless miniaturized actuator that can directly convert ultrasound into mechanical work. We apply our new, patented actuation scheme to build the first ultrasound powered endoscope.

Our approach: Our idea is to design functional surfaces that are excited by ultrasound and directly generate a force. For this we exploit acoustic streaming, where a resonant bubble can cause fast fluid flow. We fabricate surfaces that contain thousands of resonant microbubbles, which we show can actuate a millimeter-scale robot arm in a fluid (Fig. 2.1). We demonstrate that under resonant ultrasound excitation, the functional surface, which we call a Bubble Array Streaming Surface (BASS), generates a strong streaming flow, and thus provides a propulsive force that can be used for actuation. We achieve independent control of different BASS surfaces by frequency-division multiplexing, which allows us to develop a robot arm with many degrees of freedom. We also develop a method to increase the force of the actuator, such that the BASS actuator can even propel mini-robots at the centimeter-scale.

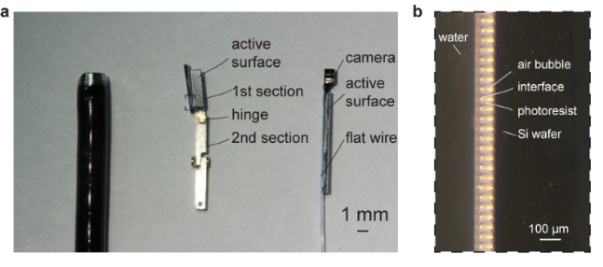

Figure 2.2: (a) Comparison of a commercial endoscope (left) with our ultrasonic mini-arm (middle) and the flexible endoscope (right). (b) Microscope image of the active surface under water, which consists of an array of micro-bubbles.

Results: The functional surfaces, consisting of two-dimensional arrays of cylindrical cavities, were fabricated by a photolithography process. When remotely powered by an acoustic field, the surfaces provide highly directional propulsive forces in fluids via acoustic streaming. The size of the microcavities and hence bubbles determines the resonance frequency. This can be exploited to independently address different surfaces, simply by changing the frequency of the ultrasound. We easily obtain more than 10 degrees of freedom, thus permitting the wireless actuation of a complex motion of a flexible endoscope, which has a diameter of only ~1 mm (Fig. 2.2a).

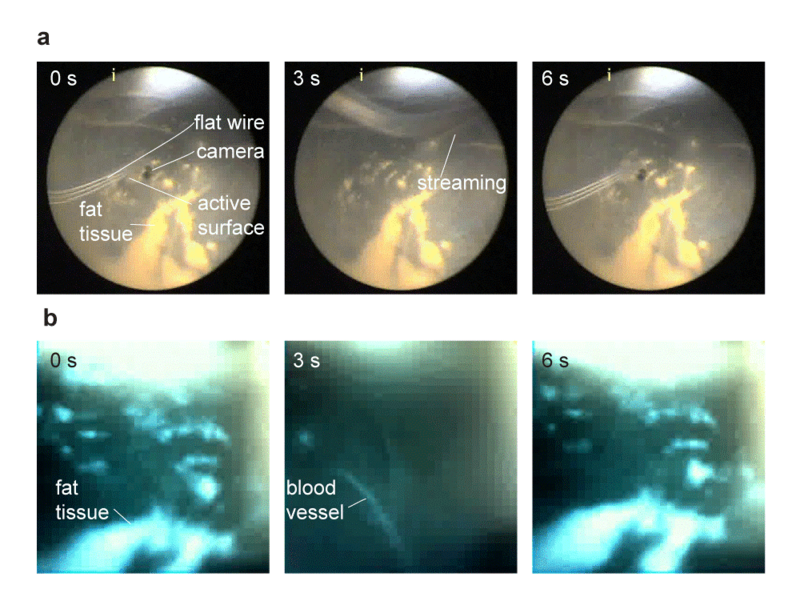

The flexible endoscope successfully performed an endoscopic examination in both a high-fidelity kidney phantom that we developed in our lab [1], as well as in a rabbit bladder ex vivo (Fig. 2.3) [4]. The flexible endoscope entered the tool channel of a rigid cystoscope, and was pointing downwards, the structure of the fat tissue can be seen as a marker (image at 0s in Fig. 2.3). When the ultrasound is applied, streaming from the active surface bends the flexible endoscope arm to the right (3 s in Fig. 2.3). A blood vessel on the bladder sidewall is clearly visualized by a 1x1mm camera.

Figure 2.3: Bladder imaging by the miniaturized flexible endoscope. (a) Snapshots of a video showing the movement of the endoscope inside a rabbit bladder. (b) Respective snapshots by the mini-camera installed on the tip of the flexible endoscope.

Discussion and Outlook: We developed a novel functional surface that is wirelessly powered by ultrasound in water and permits the actuation of miniaturized, multiple degrees-of-freedom endoscopes and robot-arms. The functional surfaces consist of arrays of micro-bubbles. Streaming can be induced with standard ultrasound sources from the outside, which ensures wireless operation. The surfaces can readily be integrated in devices. In contrast to bulk actuators, no specific consideration is needed for the mechanical coupling and integration of the surface actuators, which also minimizes the volume and weight required for actuation, thus making them particularly well-suited for miniaturization. Moreover, if the surface actuators are made of a thin polymeric material, they can also be soft and compliant with complex three-dimensional object. The adoption of micro-structured surfaces as wireless actuators opens new possibilities in the development of miniaturized devices and tools for fluidic environments that are accessible by low intensity ultrasound fields. The miniaturized endoscope arm we developed promises a significant reduction of surgical trauma and thus reduces unwanted complications for the patient.

A patent has been filed and the work has been published in Applied Physics Letters [2], Advanced Materials Interfaces (cover article) [3], as well as ACS Applied Materials & Interfaces [4]. The work was highlighted by Applied Physics Letters and by the media.

[1] F. Adams, T. Qiu, A.G. Mark, B. Fritz, L. Kramer, D. Schlager, U. Wetterauer, A. Miernik, P. Fischer, “Soft 3D-Printed Phantom of the Human Kidney with Collecting System”, Annals of Biomedical Engineering 45, pp 963–972, (2017).

[2] T. Qiu, S. Palagi, A. G. Mark, K. Melde, F. Adams, P. Fischer, “Wireless actuation with functional acoustic surfaces", Applied Physics Letters 109, 191602, (2016). Editor's pick.

[3] T. Qiu, S. Palagi, A.G. Mark, K. Melde, F. Adams, P. Fischer, “Active Acoustic Surfaces Enable the Propulsion of a Wireless Robot", Advanced Materials Interfaces 4, 1700933, (2017), Cover article.

[4] T. Qiu, F. Adams, S. Palagi, K. Melde, A.G. Mark, U. Wetterauer, A. Miernik, P. Fischer, “Wireless Acoustic-Surface Actuators for Miniaturized Endoscopes”, ACS Applied Materials & Interfaces 9, pp 42536–42543, (2017).